Loading Dock Bumpers

Loading dock bumpers are critical components of your warehouse protection plan and can help prevent significant damage to vehicles, docks, and buildings. When you think about the job dock bumpers do, they get hit by trucks over and over… and over; paying as little as possible for them would seem to make sense. High-traffic docks with the right bumpers can save money, reduce maintenance, and avoid dock closures.

Dock Bumpers Save Docks. And Trailers. And Money.

Correctly positioned and maintained, dock bumpers protect: trailers being loaded, the loading dock, including the concrete foundation, and all dock equipment such as dock leveler, dock seal, etc. The damage that results from an inadequately protected dock can add up fast.

Ideal Warehouse Loading Dock Bumpers

Ideal Warehouse Loading Dock Bumpers offer best-in-class features and benefits. A long-time leader in the dock bumper market, Ideal Warehouse Innovations can offer the best solution for virtually any dock environment. They control every aspect of the dock bumper production process, all in the name of ensuring the highest quality bumpers.

Our rubber bumpers are built from the most rigid, durable, engineered rubber, recycled truck tires. Truck tire vastly outperforms recycled conveyor belt material and molded rubber products. An environmental choice, for every bumper we create, two tires are kept out of the landfill.

Slide-EFffect®

The Dock Bumper With Moves. Covered by a Lifetime Warranty

The newest dock bumper is a revolution in loading dock protection. The SLIDE-effect® dock bumper absorbs the trailer’s impact after the trailer reverses into its dock position and features a built-in sliding mechanism to limit friction and abrasion’s effect on the bumper’s life. With the optional Tilting Bracket, the SLIDE-effect® can be manufactured with the perfect impact angle for declined docks.

Steel-Faced Bumpers

The Strongest Form Of Loading Dock Impact Protection!

Our Steel-Faced Bumpers offer outstanding resistance to abrasion from the up and down trailer movement caused by forklifts entering/exiting the trailer.

For use in high-traffic docks, the 3/8” (9.5 mm) heavy-duty steel face “floats” to allow the bumper to compress while providing high surface abrasion protection

Laminated Bumpers

A Resilient Method Of Protecting Loading Docks In Low To Medium Traffic Applications.

Laminated Dock Bumpers s are durable for protecting docks in low to medium traffic applications. Manufactured from reclaimed, bias-ply truck tires, Additional durability is gained with robust, 3/8” thick steel angles as the structural anchoring point to the dock.

Uses:

- For use in low to medium traffic loading docks in factories and warehouses.

- It can be used as rub rails at the sides of truck wells.

- Customized construction features can accommodate unusual anchoring conditions (i.e., flat plate on one side for welding to dock leveler curb angle).

- Wall protection to absorb forklift impacts

Molded Rubber Dock Bumpers

An Economical Method Of Protecting Loading Docks In Low To Medium Traffic Situations.

Molded Rubber Dock Bumpers are an economical method for protecting docks in low to medium traffic applications. Manufactured from reinforced prime rubber in several sizes, they can also be applied beyond the loading dock as rub rails along walls and impact protection from forklifts.

Uses:

- For use in low to medium traffic loading docks in factories and warehouses.

- It can be used as rub rails at the sides of truck wells.

- Wall protection to absorb forklift impacts

MAINTENANCE: When To Replace A Worn Out Damaged Dock Bumper

Replacing dock bumpers when worn or damaged is critical to preventing damage to surrounding dock equipment and building.

Look For Signs Of Bumper Fatigue:

Molded Rubber Dock Bumpers

- If they are cracked or chunking out

- If they are worn down by 1/2” or more

Laminated Dock Bumpers

- If side steel is rolled over or beginning to roll over

- If the rubber face has worn away by 3/8” or more

- If the bumper is not made with tire rubber

Steel-Faced Dock Bumpers

- If it appears the face of the bumper has become severely bent, and its impact absorption qualities can no longer function effectively

SLIDE-effect® Bumpers

- SLIDE-effect® Bumpers are installed with a permanent wall bracket and require little maintenance. Still, the day will come, so look to replace when:

- Replace the bumper only once the sacrificial aluminum track system has worn thin or when the bumper is no longer sliding up and down during the loading operation.

Allied Solutions Dock Bumpers

Allied Solutions gives you a choice between two varieties of bumper blocks, laminated and molded to match your application needs. Dock Bumpers help protect against structural damage to buildings and docks caused by trucks. They will help cut maintenance costs and expensive repairs.

Laminated Bumpers

- Absorbs over 80% of truck impact and shock to protect dock and building

- Constructed to last and provide years of protection

- Performs on any truck dock under any weather condition or prolonged exposure

- Anchored through thick steel angles to provide stability and shape retention

- Eliminates costly repairs from severe shock to docks

Molded Bumpers

- Maintenance-Free

- Will not warp, rust, rot or harden

- Molded in one piece

- It offers the correct amount of resiliency to absorb pressure and impact shock without damage to the truck or dock

- Immune to all weather conditions

Bumper Guide

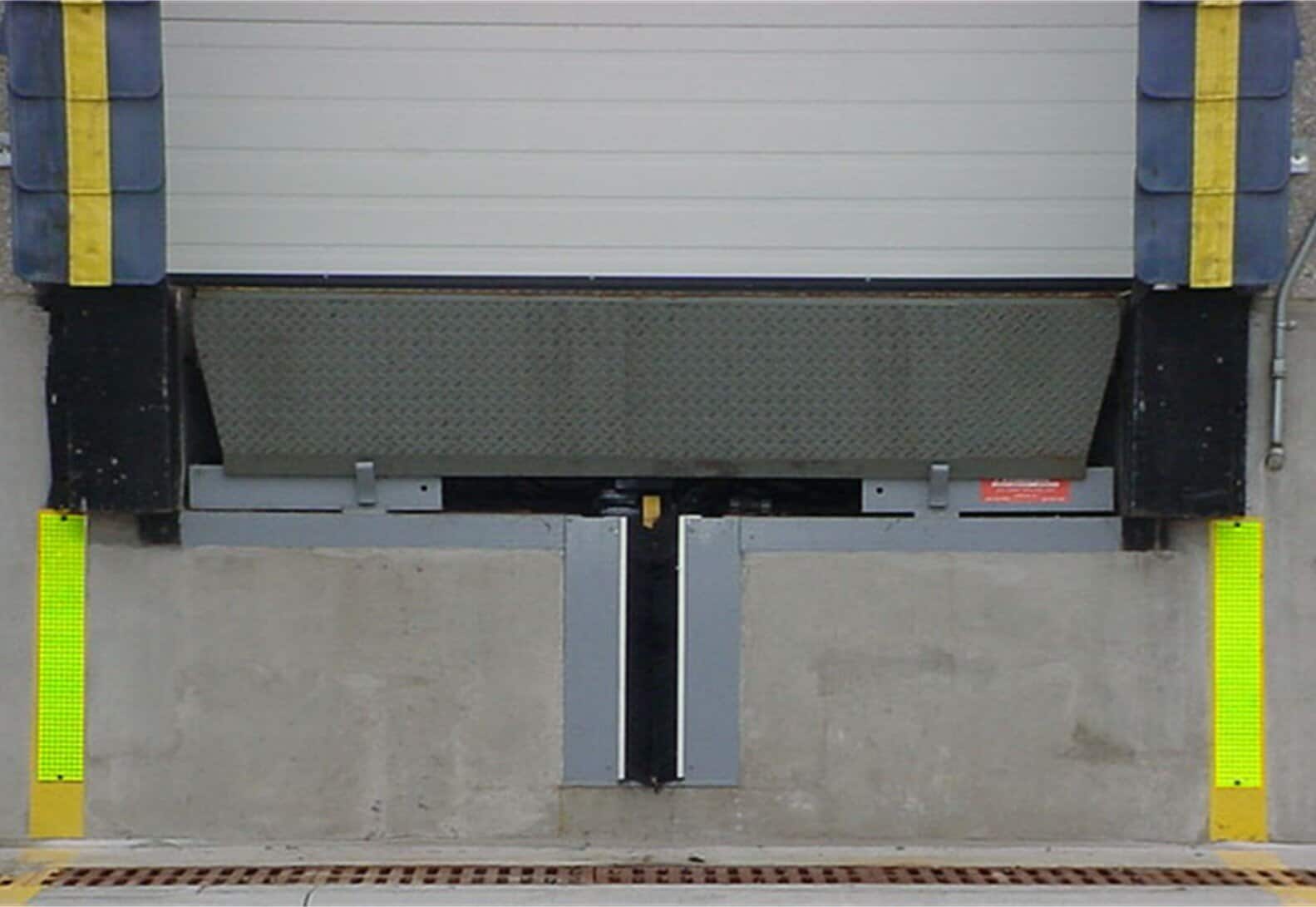

The bumper guide improves visibility when backing up to a loading dock by using multi-directional, laser printed reflective materials. The bumper guide highlights the bumper area to the left and right of the dock doors providing a clear drive line for the backing truck.

Designed with low-light applications in mind and compatible with any type of dock. The bumper guide strips are also aluminum backed to prevent rust and UV protected for maximum life.

Features:

- Reflects both sunlight and vehicle lights

- Aluminum backed to prevent rust

- Installs in minutes using drive-in concrete anchors

- Multi-directional, laser printed reflective materials accentuate the drive line

- Improves visibility, making it easier for the truck driver to position at the dock

- Designed with low-light applications in mind (inside docks, night loading, shaded building)

- UV protected for maximum life

- Compatible with any type of dock (Pit Style, EOD, Vertical, Scissors)

When selecting dock bumpers, there are several considerations to keep in mind:

Dock approach. Generally, a thicker bumper will be necessary with a declined approach and thinner with an inclined approach.

Dock height. The dock’s height determines the length or quantity of dock bumpers required.

Mounting face conditions. The condition and type of the mounting surface will influence the kind of bumper used and how it is mounted and installed.

Types of trucks. Depending on the variety, varying truck heights may require multiple rows of bumpers.

Typical truck suspension. Air-ride trailers use a suspension system; this allows trailers to shift towards and away from the dock during loading and unloading, potentially causing damage.

Traffic. Consider the quantity and frequency of trailers and choose a durable bumper to handle the traffic.

Call us at (480) 764-4255

Spectrum Facility Solutions, Commercial Doors – 3017 N Maple, Mesa, AZ 85215

Request Facility Services

JOIN OUR TEAM!

We are always accepting applications to find individuals as devoted and driven as our installation team.